Everything posted by krom

-

Arctic cat in trouble??

On November 28, 2023, the Board of Directors of Textron Inc. approved a restructuring plan developed by management in connection with the Company’s annual operating plan process. The plan will reduce operating expenses through headcount reductions at the Industrial, Bell and Textron Systems segments. In the Industrial segment, the plan includes headcount reductions at Textron Specialized Vehicles, resulting from lower demand for certain of our powersports products which we anticipate will continue, and at Kautex, due to reduced demand for fuel systems from European automotive manufacturers. In both the Bell and Textron Systems segments, the plan includes targeted headcount reductions to improve the segments’ cost structures and realign their workforces as these segments transition from legacy production contracts to more development, engineering focused contracts. Collectively, these actions are expected to result in the reduction of approximately 725 positions across the impacted segments, representing 2% of our global workforce. The restructuring plan is also expected to result in impairment charges related to both fixed and intangible assets within the powersports product line at Textron Specialized Vehicles and fixed assets at Kautex, resulting from lower planned production levels due to the impact of lower demand, which we anticipate will continue. A lot of folks have been worried the catalyst was too little too late for a long time now

-

Arctic cat in trouble??

TSV is arctic cat, tracker, cushman, jacobson, ez-go, textron motors at least. Kautex is a gas tank/fuel system systems co afik

-

Ski doo G5 chaincase least reliable drive built in the last 30 years

No one at brp is going to spend a single penny developing and producing parts to make it easier to swap a track. It's got to save $$ on paper before making it past the idea stage. My bet is it allows them to fully assemble the chaincase at a supplier, or in a different area of the factory, then just slam it on the sled, instead of playing with all the finicky little pieces going down the line.

-

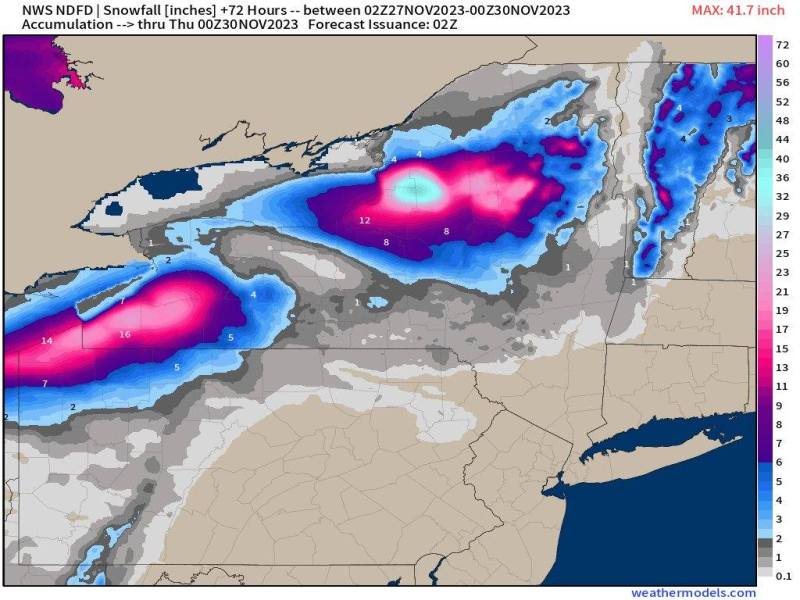

El Niño 2023/2024 - winter is canceled

I wouldn't be surprised, in 1997 the area has got 77 inches in 24 hours.

-

El Niño 2023/2024 - winter is canceled

-

Ski doo G5 chaincase least reliable drive built in the last 30 years

Guy in the video had quite a few pictures of failure... FWIW you don't believe it was done for any reason other than to lower costs at the factory, do you???

-

CATALYST Quality Ooops- Reposted from HCS/SnoWest

whats the difference between threads in a nut vs threads in a the spindle?? Most of the bolts in your 500 just thread into aluminum, Hell the bulkhead is held to the tunnel with self tappers

-

El Niño 2023/2024 - winter is canceled

-

CATALYST Quality Ooops- Reposted from HCS/SnoWest

The bolt doesn't care if its threaded into aluminum or steel, when it comes to backing out. Pretty much every skid frame is held together with bolts threaded into aluminum, and those all see way more force and abuse than the upper ball joint bolt ever would. Just look what holds the rear arm to the rails on most sleds

-

Ski doo G5 chaincase least reliable drive built in the last 30 years

how long is the tunnel going to stay that white?? Only reason I can imagine to make a change like that is if the time saved on the assy line by stuffing in an assembled chain case vastly outweighed the added cost of parts and warranty of the 2 piece shaft.

-

CATALYST Quality Ooops- Reposted from HCS/SnoWest

- CATALYST Quality Ooops- Reposted from HCS/SnoWest

my bet is that jose didn't tighten it all the way, or used the wrong bolt somehow...- CATALYST Quality Ooops- Reposted from HCS/SnoWest

bolt is an 8mm class 10.9 that threads into the aluminum spindle. Class 10.9 Alloy steel, quenched and tempered Proof Load 830 MPa Min. Yield Strength 940 MPa Min. Tensile Strength 1040 MPa so yield strenght of the bolt is 7711 lbs- CATALYST Quality Ooops- Reposted from HCS/SnoWest

I'm not jimwit so this didn't come from my buddies uncles cousin, but what I've been told in the past is that the fasteners come to the factory with patch-lock on them, and get tightened with a dc torque tool. Eso no significa que los trabajadores aprieten los pernos- El Niño 2023/2024 - winter is canceled

tug has a lot of seasonal and logging roads, that can be ridden dusk to dawn afik (I know they always are, legal or not) most of the state's trails are closed till dusk on the last day of hunting season (which varies depending on what region you are in, and if they are running some special late hunt) State plow just went buy as I'm typing this, about a half inch on the ground here. the DOT guys must be pushing for OT to make up for the thin paychecks last winter- El Niño 2023/2024 - winter is canceled

- CATALYST Quality Ooops- Reposted from HCS/SnoWest

AC has been using that bolt/trinut setup for years now on the M's and G2 sleds- Ski doo G5 chaincase least reliable drive built in the last 30 years

good eye.. This entire thing is hilarious after the doo guys bashing AC for the procross chain case. Pretty much every sled AC has built for the last 8 years including the blast has a much stronger hyvo chain and gears than what doo is putting in their turbos. Just to repeat my self, the blast comes with a stronger hyvo chain and gear setup than doo uses on their turbo sleds- Ski doo G5 chaincase least reliable drive built in the last 30 years

That sure looks like the junk gear that breaks and leaves you stranded....- Snocross 2024

iron dog gets 0 publicity, the majority of sledders have no idea what it is. .. Their major media outlet is somebody's personal blog- Ski doo G5 chaincase least reliable drive built in the last 30 years

- Polaris is giving out more free parts again...

There are poo's with over 10 stop rides on them- 23/24 Cross Country thread

Other than turning into octagons I haven't seen any rear failures of the newest style ac rear wheels, and we've sold very few of them over the counter. I do recommend adding a 4th wheel for the guys I know who ride hard, but its stupid cheap to do using factory parts. The smaller idlers in the rest of the skid frame are another story, pretty common for them to hit the eject button on the trail- 23/24 Cross Country thread

Ouch, almost double AC had to go to 1,2,3 because too many jimwits who don't have the slightest idea what the "clickers" do are buying the rr and rxc- 23/24 Cross Country thread

DSC used to be around $100 ea plus oil and nitrogen, haven't priced them in 2 years - CATALYST Quality Ooops- Reposted from HCS/SnoWest