favoritos

-

Joined

-

Last visited

Posts posted by favoritos

-

-

20 minutes ago, Allyammies said:

Yes front track shock spring. I'm 270 kinda knew going in this may be a problem. ZR 137. I would bottom on my Viper on some of the same shit.

I don't have part numbers but the Catalyst 137 front arm is using the same shock as Procross has been.

Unfortunately, the RXC springs would not be a good match since they are using the the same larger diameter as the old RR sleds.

@jonlafon1, I still have one of those lighter initial rate RR springs sitting around. I always swapped them out for a heavier spring. The RXC is using the same setup they RR had for springs except for that light spring. You can have that spring to try if you like. Unfortunately the isolation collar shock rub etc. is going to be the same as we've seen on the RR setup.

-

3 hours ago, jonlafon1 said:

Thanks for update.

Got an imbalance in the clutching with that much dust! So these sleds have a big helix angle compared to years past I’m sensing and reading. Usually when we go to steep big helix we need way less weight in primary and way more spring in secondary. Just food for thought. By going to a softer secondary spring you could be making it worse with the big stock helix. . I have no miles on mine but it sounds like clutch work will be a need once again from a stocker Cat sled. I do have a slightly softer secondary spring but going to try stock with the exception of the heavy hitter weights I put in.Looking back at the 23 600 clutching, they used the same secondary spring we have and a straight 48 helix. Primary has same weights but the heavier initial rate 85 vs 65 on Catalyst. Finish was 225 vs. 255 on Catalyst. (85/225 on 23 and 65/255 on Catalyst)

I have no idea how the 23 600 ran on belt heat. Maybe someone else has an input. The straight 48 helix is interesting with the 23 600 sleds.

I get the idea of easier pulling on the Catalyst, but the clutching is off. Both years are using the same finish rate and angle in the secondary. Same weights too. Primaries are shimmed fat on the Catalyst and the spring has a higher finish rate. The primary just can't do a full shift unless they are on pure ice.

If the 23 600 ran well, I'd love to find a primary spring in the 65/220 range and try that simple change. Cat has a 45/225 spring, but I think it will be a bogger off the line with fat shimming.

-

Edited by favoritos

13 hours ago, jonlafon1 said:Yea figured that. My 2021 was the same kinda electric whine sound. It’s when you’re in that 15-25 or so. Letting off And coming down off speed I hear something. Clutch noise whatever you call it. I call it c a electric whine sound

Throw on an old crusty belt with dirty sheaves and the noise will go bye bye.

The Rapid Response and ADAPT clutches hold side pressure tight at low speeds and the noise is the belt contacting and breaking from the sheave faces. The sound is more notable when clutch faces are clean, and the belt is new with more soft rubber edges protruding from cogs etc.

Most newer stock setups also come with high backshift pressure. The belts are just simply tighter.

The chirp from engagement is gone, but we hear the tight belt now.

The other quick solution is to just drive fast.

Engine sound, wind noise, and track, all get louder so you don't hear the belt making and breaking contact.

Engine sound, wind noise, and track, all get louder so you don't hear the belt making and breaking contact.

-

1 hour ago, jonlafon1 said:

I believe we are seeing very few Kashima shocks is because FOX had a hard time providing them? The last couple years sleds were late to customers because Cat was waiting on FOX/kashima coated shocks? Can anyone tell the difference? Doubt it very highly.. Maybe some big time pro racers can but the average guy riding down the trail > not a chance..

Anything with the coating had to be funneled through a single facility way outside the borders of North America. Quite a few bigger players in the bike market started offering the coating. We'll leave it at that.

Lot's of debate about the topic. In my situation, they were beneficial. I'm not a heavy rider. The shocks start moving easier with my weight on the sled. I am able to adjust the settings and use full travel easier. Riding buds are big guys and that feature didn't add much for them. Honestly, it may even be a detriment. They rarely ever adjust a thing. If their sleds bottom out, they crank up spring pressure. With easier moving shocks, they would over spring the suspensions.

Most of the stock shock packages work quite well for bigger guys especially if they don't like adjusting. Let's be honest, most people prefer a set it and forget it configuration. I also like that way of setup and riding if it's an option. With some shock setups it wasn't easy. Suspension travel becomes a game of all or nothing with lighter riders and shocks that don't like to start moving. I'd set the spring pressure so I could get the suspension moving and then it would be prone to bottoming quickly. That scenario is a PIA for an aggressive rider that likes a good setup. I spent a lot of effort with some stock shocks getting them valved for my riding. I could adjust the RR coated shocks without tearing them apart and revalving. Settings didn't fall into the all or nothing category of suspension travel. That was a big deal for me. Way less time spent dinking around with getting the shocks to work right and settings that were actually incremental.

-

I have fiddled around with rebound. The rear shock was a springer when I got the sled. Way too much rebound. That little screw is touchy. I even get a little nervous about over cranking the bugger.

The shock package is surprisingly similar to the RR setup minus Kashima coat, from what I can determine. Valving is very close and the big guys won't mind the stiffer RXC rear arm. They still have a lot of range to adjust up or down on pressure and valving. Lighter riders are right at the limit of adjustment on that end. Honestly, the RXC is more compliant than I expected. The rear arm setup stands out because it cranks tight faster and coupling really highlights the settings.

I got spoiled with the RR sleds because I had a bigger range of usable adjustments right out of the crate. I could dial those things dead nuts on for my weight and still adjust up and down for conditions.

-

3 hours ago, Crnr2Crnr said:

found another torsion option... ZR 137 ATAC uses 0.375 95degree 15.2lb part # 4704-152 & 4704-153

fwiw

That is interesting info. I have one of those to ride and compare.

I honestly think the rear arm on the RXC has a hair too much spring for a balanced setup.

Finally found a place to look up parts for these things. I wonder if those two rear arms are a different configuration with angle and spring mounts? The RXC has a beefer arm with reinforced link mounts and different spring sleeves. I'm sure I'd need the correct sleeves at the very least to keep the spring from turning into a clanger.

-

35 minutes ago, jonlafon1 said:

What did you adjust? Pull coupler blocks? Nice post, thanks for info

I have an old dial adjust that has one side ground down to 1/8" over the shaft. I've ground one side of the stockers in the past, but I figured I'd do some testing with this thing first.

The coupling is pretty harsh on these with the skid changes. It's hard to collapse the rear arm with tight coupling. That's great if you want to ride flat all day. It tends to spin out easier on launch and across bigger hits. I prefer a little more transfer.

-

22 hours ago, Crnr2Crnr said:

ok... torsions.

ZR 129 uses 0.359" 100 degree 12lb torsions

RXC uses 0.394" 90 degree 16.5lb torsions

for the 129" they made a heavy spring kit with a pair of torsions that are the same as the 24 RXC uses... 8639-544 which is $145 for the pair.

so there's hope...

I'm glad you found the info and posted. It's a bear trying to dial in and adjust these things without riding.

I had the RR sleds dialed in for my style over the years. I figured it wouldn't hurt to use those numbers as a cross reference starting point.

First of all, I'll note that the new RXC isn't set up race ready like the old versions. Personally I'm fine with that. Rider weight becomes a factor and some of the super stiff setups make it hard to use full suspension travel except in big hits.

Ski shock springs on the new RXC are same specs as the RR.

The new RXC FTS spring is the same setup I used on the old RR sleds. They came with a stock initial rate that was too light and it slammed through the travel. I always swapped out the spring for the one now on the RXC. I'll see how valving works out, but it feels dang close to the RR.

The RXC rear springs spec the same as the RR sleds on paper. It is the same spec description used on quite a few previous sleds. With the the skid changes, it acts much stiffer. Spring part numbers are different, so I'm wondering if there is something I'm missing.

Either way, the Catalyst RXC is incredibly compliant except on the rear arm. I've done a lot of floor setups over the years and it's notable. We'll see how it breaks in. Right now, it gets lock up stiff when the front arm couples. I'm already opening up coupling to use the rear arm more effectively.

-

@jonlafon1 Nice work on digging into the clutching. These are easier to break down and replace parts.

I have only seen the green spacer in previous clutches. They seem odd because they just "float" until they contact. I wonder if the white is thicker? My understanding is they are important to prevent overclocking the weights. The weights do have contact closer to the end vs. the old clutches.

I agree that the cover seems awful light. It will flex if you goof around and tighten one side at a time. Lazy wrenchers might have issues.

Not sure if the roller bushings were changed? They were full length, but in two sections pressed from each side.

I compared the weights on two new sets last season. The low to high variance was .31 g with two outliers making up most of the difference. I also checked roller to weight variance on a few clutches. They were pretty close and within .007 on the worst one. I had some old clutches that were off by quite a bit. I had a TEAM that was almost .030 right out of the box.

I'd agree that the helix bolts seem short. I have not had any of these break loose. I do keep spare sets on hand and swap in new if they've seen multiple rounds. That's an old habit I still use. I also like to clean the threads to make sure they get correct torque with such short contact area.

-

-

On 12/17/2023 at 7:04 PM, Palu49 said:

They did it during break in with the electronic oil pump too it’s getting a fuck ton of oil and not sucking it all through starting it up and letting it idle “heat cycling” it

They use more oil with the electronic pump during the early break in. Nobody ever mixed break in tanks at that ratio.

We bring extra oil for the first rides with new sleds. It's crazy how much they use.

-

On 12/10/2023 at 8:58 AM, jonlafon1 said:

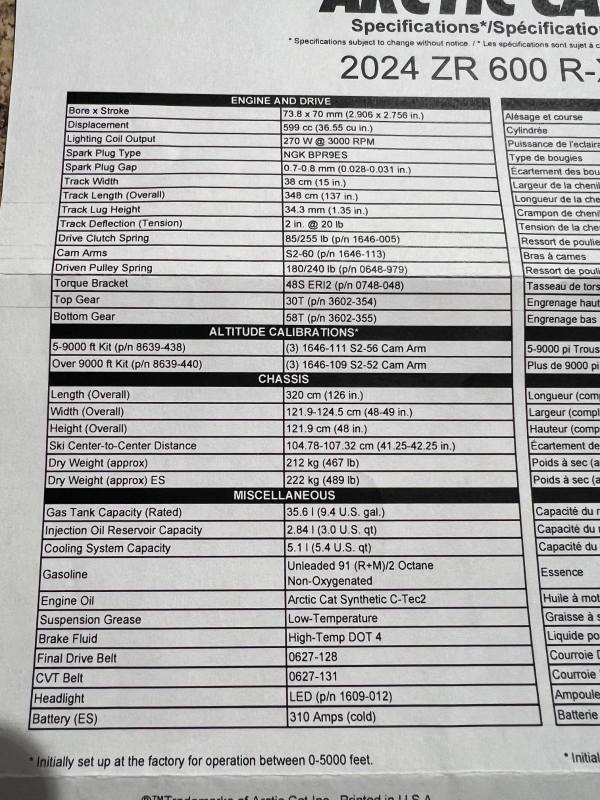

Thanks for posting the spec sheet.

The secondary info is nice to know.

I'm guessing that is a straight cut helix? I'm never sure with some of the numbers I've seen over the years.

It looks like the same secondary they have used with earlier RXC sleds. The primary is setup different. Those 60g weights and high finish rate spring could be interesting. I'm guessing we will see some screaming rpms on these.

I wonder if the other models are running the same clutching? Can't find the parts diagrams.

-

-

Are the shorter nuts steel?

I retorque the studs on mine each season. The aluminum tall nuts do seem to need more turns on the first round of checking. I'm not sure why. They seem pretty good after that first check. I also replace any backers and studs that look really whacked. Once and awhile I'll find studs bent enough that they need the ol grinder cutoff which is surprisingly efficient.

One thing I'll say about the practice of checking and retorquing. I don't think I've lost any since I started doing that process. Buddies still lose studs every so often and they run the same brand and style.

-

Glad to see part diagrams are starting to show.

I don't have a clue if the screw is aluminum. The description does look that way. I don't recall ever seeing a shoulder bolt made of aluminum. Honestly, it wouldn't be a good design if that is the case. Shoulder bolts are nice in the fact that they seat and bottom out nicely. That feature would be a problem with stretchy composition material. It would not be a reusable bolt for that application.

-

On 11/24/2023 at 1:12 PM, Crnr2Crnr said:

Is that arm bent? I admittedly have no idea how the short arms are shaped.

It's always hard to tell what is exactly happening with some of these posts. Seems odd if all the blue gunk on the nut and arm is extra locktite.

On the other hand, I'm not a big fan of threading a steel bolt into the thin aluminum upper spindle section if that's how they are built. I see the potential for too many back yard hacks going full bore on the bolt and splitting the spindle. That point is weaker than the steel A arm section with the bolt.

-

@Crnr2Crnr, It's funny that you mention the wheels. I'm not sure what direction I'm headed with the Catalyst sleds. I have not had time to look at the parts diagrams.

The standard skids looked like they may ship with the previous version of octagoners. The RXC proto sleds looked like better wheels along the rails. If they are using the octagoners, I'll put in better wheels. If they ship with the old stock PPD wheels, I might just run em. Those are good enough and they are cheap. I usually swap in better bearings. The Soucy wheels are super durable and have half a dozen sitting. I don't know if I need something that durable. They add rolling weight and the stock bearings are so so. With good bearings, the wheels are pretty dang good, but it takes some coin.

I have a spare Larson kit for the rear. I'll put that on one sled just because. The tensioner setup is easier and more durable than stock. I like the more durable wheels. The bearings are maybe a little better, (I swap in better bearings on the first replacement).

Overall, I don't have a concrete plan with what I'm doing. I like to run the sleds and see what breaks.

-

I remember years ago when Bush came flapping into town for an event.

One stretch of highway I drove every day was to be used for their drive to and from the airport for the event. They sure did clean up that stretch. The tents were removed from under the overpasses, graffiti was removed, and the whole roadside was tuned up. They planted trees, grass and flowers. The mowing crew switched to better equipment and did a really nice looking roadside.

It seemed like quite the effort along that road for a simple drive. The work I saw took quite a few weeks. I'd be surprised if Bush caught more than a quick glance.

Ironically, the initial trash cleaning looked like those prison van crews. I'm not sure if they caught the irony.

-

36 minutes ago, Not greg b said:

I wasn’t spending 2 grand for a shitty computer controlled one setting shock. Iact sleds and riots were the easiest to find. If it was like the mag used in gm sports cars or brp products then it would be worth getting

It's three settings.

I'm surprised how little that adjustment gets changed. I don't ride the ATAC sled a whole lot, but it's rare to move the setting. The shocks are kinda meh and certainly work better with big guys. They seem to get the shocks moving enough to get travel and notice the difference.

It seems like a cool feature, but it's a poor choice for myself with the current setup. I'd love to see Cat do a little fine tuning. They could knock it out of the park with the simple bar adjustment process on the IACT sleds. Add some manual adjustment to the presets and let users toggle between setting that work for them.

It still blows me away that I have had the best luck with a sled they call the RR. The name throws people off. Those shocks are actually adjustable. I can set them up for my weight and ride harder with way less effort.

-

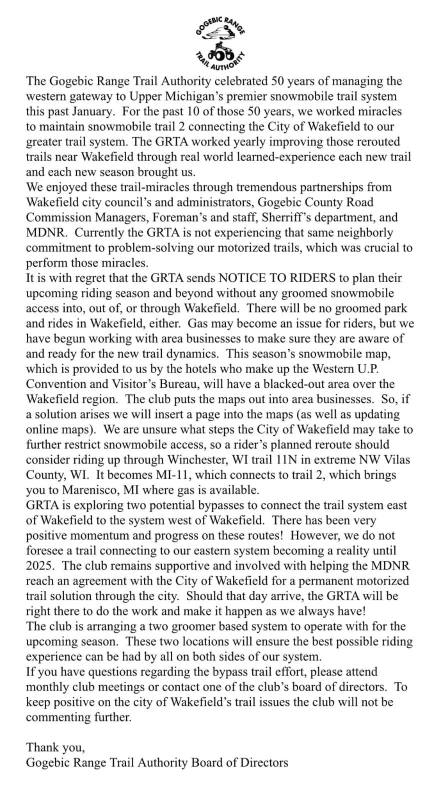

Not sure if there are going to be many options. One of the kids sent me this post off FB.

Looks like we might be trying the idea @jonlafon1 has suggested.

-

Last year's reroute was a huge improvement. It was fun to ride the stretch of old grade we used to use for trail. Sadly, I also saw two ding dongs off trail and stuck right in a section marked "stay on trail". One guy looked like he was in someone's yard. I was pissed. It was tempting to hang around and chew them out. I sure as hell wasn't going to crawl through the drifts or help them out, so I let it go. Hopefully they got some form of Karma for that bonehead move.

@Ziemann Yeah, Bingo's was perfect for sledding. He had the whole setup. We even used the shop once and awhile. It was nice to be out of town, but close enough if you needed.

We also used to ride the back trail up to S Boundry. Trail 11N ran right along 519 for a distance. That was a fun trail. I've towed sleds on the road, but never really rode it for much distance. The bugger was a carbide burner most of the time when we tried. i don't think I've ever rode the Camp 4 Grade. Looking at the map, trail 102 must end up close to the same spot. It was amazing on some days how much the snow changed riding up that direction. We had a few times when new snow was barely enough to cover grass at Bingos and measured in feet up on the hill. Last season would have been a good time to see that happen. We ran into big LES storms on a few trips.

-

Thanks @jonlafon1 for clearing up the 11S route. I'm somewhat familiar with the area, but that trail seemed to be so inconsistent that we quit trying. It was easier to give a quick try when Bingos was still around. (That was our home base about five weeks per season.) I can't even guess how many times I've rode through that intersection.

We gave 11S another shot early last season right after the doozy Christmas snow, but it hadn't been touched yet. We also had a brand new rider and one new sled. Those aren't the best terms for breaking trail. We just aimed for Marenisco before the mini mart gas closed. I have to admit that the renaming of trails was also a little confusing with the "new 2 grade section and the old 2 being 11" in the area south of Wakefield. I'm not even sure when that was changed, but one of the boys pulled up trail app and noted that name was different.

@Doug I've followed the discussions about the ski hill owners. I often wonder where there money comes from with the way they do business. I can imagine that the double talk flows through their operations.

BTW, the current GRTA is a world apart from the old group. They have done quite the improvement. I'm sure it will take years before people get past the old perceptions of junk trails. I'm sure it hasn't been easy to change the culture, but they really upped their game. We joke about their trails being the dirty little secret on that end now. It's refreshing to ride through there. In the big picture, trail 2 corridor section is just plain tough. That's a tight stretch without many reroute options.

-

Last season's temporary route was pretty easy with all the snow. The stretch on the road shoulder was better than I expected. Granted, the good snow was a big factor, but it was better than the route around the ski hills.

@jonlafon1, I have not been across the 11S trail for quite a few years. That thing seemed like it was partially closed quite often. Even tried early last season, and ran out of trail. Are you using roads vs. the trail?

The trail 2 thing sure is a pain. We used to base right out of Wakefield and it just became more and more hassle. Thank God we didn't buy a place there.

I often wonder if the local population has a clue how much that trail matters? The area is becoming the end of the world in terms of riding. It's hard to get through there compared to the old days and people just base further away.

-

20 hours ago, teamgreen02 said:

I bought the tool bag from Klim and walked around Harbor Freight for 10 minutes. I'll try to remember to take a picture of what I put in there.

How is that bag?

I have been using a tool wrap for years that worked quite well. It was small enough to carry on the bars and kept the tools tight with a cinch strap/buckle system. The variety of pockets worked well with some sewn tight along with adjustable velcro versions. I see that the bag has been discontinued and I've been on a quest to find a suitable replacement. It seems like quite a few bags are too big and cumbersome.

Sounds like many of us have a similar method for tools. We carry just the tools we need. We also need them easy to access and use in cold.

2024 Arctic Cat Catalyst 'Chassis' details?

in HCS General Forum

I wonder if some RXC sleds were set up using the rear set of holes? Those are too far back and up for the blocks to hit square.