favoritos

-

Posts

547 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by favoritos

-

-

@Palu49, I curious to see how the primary rpms out. What spring did you decide with the weights?

I wonder if we both did the same thing on the secondary?

I wish I would have bought a couple more when I saw the loaded setup cheap this spring.

I wish I would have bought a couple more when I saw the loaded setup cheap this spring.

-

We were up there last week. Rode Wakefield, Bergland, and Bruce early in the week and did Copper Harbor later in week. I would bring plenty of carbides and hyfax if they want to think about riding. Trail 3 was already done south of Twin Lakes.

I think the biggest bummer is the fact we could ride early in the week if we stayed north. That was already fading by late week and I'd be shocked if it's rideable now. Without the extended meltdown, it would have been easier to save the trails.

One oddball thing with the snow this season was the depth right next to the lake. It often drops anytime you are close enough to see the water. Those stretches actually had snow this year.

It was a real bummer to see some of our favorite places with empty parking lots. We even went to an old place (Fishtales) with new owners on Gogebic. The new owners changed the name to Finn and Feather? I'm honestly not positive, but the food was damn good. I sure hope they make it through this season.

-

2

2

-

-

I've seen loose tracks slow us down when they rub in the tunnel. It can be pretty significant.

How tight is too tight, I don't know on that side.

For the record. The Cobra and Rip II tracks have both stretched a lot this year. Two rounds of retightening so far on both with only 550 miles. I usually need at least one round this early and they settle down.

-

1

1

-

-

2 hours ago, Doug said:

Go to a place that does vinyl wraps and get some black to go on the tunnel before assembly. For rivets use stainless and paint them.

I bet you can find stainless rivets that are already coated black. I've used those on repairs and keep a pile on hand.

Not sure about the wrap idea if you're talking about putting it between tunnel and repair. I like structural sections riveted together tight. If talking about covering the final, go for it if you want.

-

9 hours ago, Not greg b said:

Is it ok to pry the adapt open with a screw driver and use a piece of wood to hold it open to change the weights? I looks like a pain in the ass to get my puller out and 1 inch impact to take the clutch off. I will spray it with wd40 so it slides open easier so it won’t hurt anything.

I just pop the cover off without pulling the clutch most of the time. I've changed weights along the trail with that method.

I looked at the Catalyst before changing weights and didn't even bother trying to pull the clutch. After all, I was only changing weights. No need to tear the side belly pan apart.

I did pull the two T25 screws to allow a little more flex on the panel.

Also worth noting. The spring pressure is super light. Compressing the cover is a two finger jobber when putting the thing back on.

-

2

2

-

-

1 hour ago, Palu49 said:

All of them but one that I put together and serviced were perfect with the 90 and 30 shims (IIRC) they came with. 1.507” is the cat tool so sounds like yours is right on the money too.

Mine came with a .090 and .060 which was a surprise. I've had quite a few previous sleds with the BOSS and they all had one .090 shim.

My motor on the RXC sits further left than the other one. I haven't looked at the motor mounts, but the two sleds are definitely set up different. The RXC creeps the track on the stand no matter where I align the secondary and the primary is rubbing on the gray flip down doo hickey. The other sled does neither.

-

On 1/24/2024 at 9:01 PM, Jorge said:

I just put on 450 miles on my new Catalyst. Mileage is 14.5 mpg after break in. 130 miles to a tank or so.

Dang.

I didn't see that kind of mileage. The gas stop planning was modified with the smaller tank. It wasn't a deal breaker but it was needed.

-

2 hours ago, jonlafon1 said:

I lined the compartment with THICK green felt. Great place for phone and money clip, etc.. I actually really like this compartment.. Its got power inside it also.. Yea the lid is a little cheap but I find it fine.. I do not use goggles so for me none issue.. But they should have made it big enough to fit goggles.. O well at least you can just drop the 8' garmin in the slot above.

The compartment sure does well to warm and dry stuff that fits.

I ended up modifying the mounts on a NS1 gauge and using the Cat gps bag for compartment cover.

The dang thing fits really good. The modified mounts also tilt it back a bit so I'm looking straight on vs. stock gauge tilted forward.

I also found out that the gauge location is pretty sweet if you get an ice storm overnight. I went out to clean off the sleds and the gauges were clear.

-

3

3

-

-

3 hours ago, taperk600 said:

It's an easy sled to "ride" so to speak.

I need / want to get a little more transfer out of the ZR 137 skid at trail speeds,

Funny that you mention the first line.

We put about 550 miles of pure junk miles on this week. The consensus on describing the ride is that it's easier to ride. Bud is one of those that never moves around on the sled. The easy ride thing is a huge deal for his riding. He can ride one heck of a lot better on these without moving around.

I had a hard time at first with the higher seat. I typically move to the inside of the sled and it took a little time getting used to the chassis and seat. I used to basically hug the tank before. I've found that these work with me riding further back with my feet and body. The side to side transitions are still a bit more work, but the stand-sit transition is gravy. Overall it is easier to ride in junk. I'm really becoming a fan of the way it handles the Oh shit! potholes. The chassis setup and rider position make those big hits easier.

I wouldn't call the RXC a big transfer feeling skid. I swapped between two 137 sleds this week. The RXC moves to a point and then it basically stops at coupling. Drag racing was tough in deep hardpack. It transfered good at first and then locked up on launch. The bugger was a hole digger if you hit the transfer stop point. The other sled was an ATAC version and running it on soft had better transfer in holeshots and riding bigger stutters.

Also notable for me. The seating position and bodywork makes the sleds seem faster. You feel more out in the open. There were times it seemed like we were flying through tree lined sections and the speedo was saying numbers smaller than expected. The whole feeling is a little surprising because the wind protection works pretty good except wind stream over the top.

I myself would like to see a slightly taller windshield option. The current tall version puts a lot of air right at face level. That forces me to use bulkier helmet combos to stay warm.

-

3

3

-

-

13 minutes ago, jonlafon1 said:

I noticed 3 holes on the rails for the front suspension shock lower mount.. But did not see more then ONE hole for the transfer block metal rod. I must have missed it as I took the metal rod completely out for some different wheels for in the rear.

This was mine on delivery.

Seems like there is a fair amount of room to move that front shock and tunnel cross shaft around as mentioned. I figured the extra holes were for the ice racing guys. Each adjustment from stock lowers the sled in that section. I expected to have corresponding holes for the rear scissor mounts too. That would actually make more sense for the extra coupler holes.

-

1

1

-

-

I wonder if some RXC sleds were set up using the rear set of holes? Those are too far back and up for the blocks to hit square.

-

20 minutes ago, Allyammies said:

Yes front track shock spring. I'm 270 kinda knew going in this may be a problem. ZR 137. I would bottom on my Viper on some of the same shit.

I don't have part numbers but the Catalyst 137 front arm is using the same shock as Procross has been.

Unfortunately, the RXC springs would not be a good match since they are using the the same larger diameter as the old RR sleds.

@jonlafon1, I still have one of those lighter initial rate RR springs sitting around. I always swapped them out for a heavier spring. The RXC is using the same setup they RR had for springs except for that light spring. You can have that spring to try if you like. Unfortunately the isolation collar shock rub etc. is going to be the same as we've seen on the RR setup.

-

1

1

-

-

3 hours ago, jonlafon1 said:

Thanks for update.

Got an imbalance in the clutching with that much dust! So these sleds have a big helix angle compared to years past I’m sensing and reading. Usually when we go to steep big helix we need way less weight in primary and way more spring in secondary. Just food for thought. By going to a softer secondary spring you could be making it worse with the big stock helix. . I have no miles on mine but it sounds like clutch work will be a need once again from a stocker Cat sled. I do have a slightly softer secondary spring but going to try stock with the exception of the heavy hitter weights I put in.Looking back at the 23 600 clutching, they used the same secondary spring we have and a straight 48 helix. Primary has same weights but the heavier initial rate 85 vs 65 on Catalyst. Finish was 225 vs. 255 on Catalyst. (85/225 on 23 and 65/255 on Catalyst)

I have no idea how the 23 600 ran on belt heat. Maybe someone else has an input. The straight 48 helix is interesting with the 23 600 sleds.

I get the idea of easier pulling on the Catalyst, but the clutching is off. Both years are using the same finish rate and angle in the secondary. Same weights too. Primaries are shimmed fat on the Catalyst and the spring has a higher finish rate. The primary just can't do a full shift unless they are on pure ice.

If the 23 600 ran well, I'd love to find a primary spring in the 65/220 range and try that simple change. Cat has a 45/225 spring, but I think it will be a bogger off the line with fat shimming.

-

2

2

-

-

13 hours ago, jonlafon1 said:

Yea figured that. My 2021 was the same kinda electric whine sound. It’s when you’re in that 15-25 or so. Letting off And coming down off speed I hear something. Clutch noise whatever you call it. I call it c a electric whine sound

Throw on an old crusty belt with dirty sheaves and the noise will go bye bye.

The Rapid Response and ADAPT clutches hold side pressure tight at low speeds and the noise is the belt contacting and breaking from the sheave faces. The sound is more notable when clutch faces are clean, and the belt is new with more soft rubber edges protruding from cogs etc.

Most newer stock setups also come with high backshift pressure. The belts are just simply tighter.

The chirp from engagement is gone, but we hear the tight belt now.

The other quick solution is to just drive fast.

Engine sound, wind noise, and track, all get louder so you don't hear the belt making and breaking contact.

Engine sound, wind noise, and track, all get louder so you don't hear the belt making and breaking contact.

-

2

2

-

-

1 hour ago, jonlafon1 said:

I believe we are seeing very few Kashima shocks is because FOX had a hard time providing them? The last couple years sleds were late to customers because Cat was waiting on FOX/kashima coated shocks? Can anyone tell the difference? Doubt it very highly.. Maybe some big time pro racers can but the average guy riding down the trail > not a chance..

Anything with the coating had to be funneled through a single facility way outside the borders of North America. Quite a few bigger players in the bike market started offering the coating. We'll leave it at that.

Lot's of debate about the topic. In my situation, they were beneficial. I'm not a heavy rider. The shocks start moving easier with my weight on the sled. I am able to adjust the settings and use full travel easier. Riding buds are big guys and that feature didn't add much for them. Honestly, it may even be a detriment. They rarely ever adjust a thing. If their sleds bottom out, they crank up spring pressure. With easier moving shocks, they would over spring the suspensions.

Most of the stock shock packages work quite well for bigger guys especially if they don't like adjusting. Let's be honest, most people prefer a set it and forget it configuration. I also like that way of setup and riding if it's an option. With some shock setups it wasn't easy. Suspension travel becomes a game of all or nothing with lighter riders and shocks that don't like to start moving. I'd set the spring pressure so I could get the suspension moving and then it would be prone to bottoming quickly. That scenario is a PIA for an aggressive rider that likes a good setup. I spent a lot of effort with some stock shocks getting them valved for my riding. I could adjust the RR coated shocks without tearing them apart and revalving. Settings didn't fall into the all or nothing category of suspension travel. That was a big deal for me. Way less time spent dinking around with getting the shocks to work right and settings that were actually incremental.

-

I have fiddled around with rebound. The rear shock was a springer when I got the sled. Way too much rebound. That little screw is touchy. I even get a little nervous about over cranking the bugger.

The shock package is surprisingly similar to the RR setup minus Kashima coat, from what I can determine. Valving is very close and the big guys won't mind the stiffer RXC rear arm. They still have a lot of range to adjust up or down on pressure and valving. Lighter riders are right at the limit of adjustment on that end. Honestly, the RXC is more compliant than I expected. The rear arm setup stands out because it cranks tight faster and coupling really highlights the settings.

I got spoiled with the RR sleds because I had a bigger range of usable adjustments right out of the crate. I could dial those things dead nuts on for my weight and still adjust up and down for conditions.

-

1

1

-

-

3 hours ago, Crnr2Crnr said:

found another torsion option... ZR 137 ATAC uses 0.375 95degree 15.2lb part # 4704-152 & 4704-153

fwiw

That is interesting info. I have one of those to ride and compare.

I honestly think the rear arm on the RXC has a hair too much spring for a balanced setup.

Finally found a place to look up parts for these things. I wonder if those two rear arms are a different configuration with angle and spring mounts? The RXC has a beefer arm with reinforced link mounts and different spring sleeves. I'm sure I'd need the correct sleeves at the very least to keep the spring from turning into a clanger.

-

35 minutes ago, jonlafon1 said:

What did you adjust? Pull coupler blocks? Nice post, thanks for info

I have an old dial adjust that has one side ground down to 1/8" over the shaft. I've ground one side of the stockers in the past, but I figured I'd do some testing with this thing first.

The coupling is pretty harsh on these with the skid changes. It's hard to collapse the rear arm with tight coupling. That's great if you want to ride flat all day. It tends to spin out easier on launch and across bigger hits. I prefer a little more transfer.

-

1

1

-

-

22 hours ago, Crnr2Crnr said:

ok... torsions.

ZR 129 uses 0.359" 100 degree 12lb torsions

RXC uses 0.394" 90 degree 16.5lb torsions

for the 129" they made a heavy spring kit with a pair of torsions that are the same as the 24 RXC uses... 8639-544 which is $145 for the pair.

so there's hope...

I'm glad you found the info and posted. It's a bear trying to dial in and adjust these things without riding.

I had the RR sleds dialed in for my style over the years. I figured it wouldn't hurt to use those numbers as a cross reference starting point.

First of all, I'll note that the new RXC isn't set up race ready like the old versions. Personally I'm fine with that. Rider weight becomes a factor and some of the super stiff setups make it hard to use full suspension travel except in big hits.

Ski shock springs on the new RXC are same specs as the RR.

The new RXC FTS spring is the same setup I used on the old RR sleds. They came with a stock initial rate that was too light and it slammed through the travel. I always swapped out the spring for the one now on the RXC. I'll see how valving works out, but it feels dang close to the RR.

The RXC rear springs spec the same as the RR sleds on paper. It is the same spec description used on quite a few previous sleds. With the the skid changes, it acts much stiffer. Spring part numbers are different, so I'm wondering if there is something I'm missing.

Either way, the Catalyst RXC is incredibly compliant except on the rear arm. I've done a lot of floor setups over the years and it's notable. We'll see how it breaks in. Right now, it gets lock up stiff when the front arm couples. I'm already opening up coupling to use the rear arm more effectively.

-

1

1

-

1

1

-

-

@jonlafon1 Nice work on digging into the clutching. These are easier to break down and replace parts.

I have only seen the green spacer in previous clutches. They seem odd because they just "float" until they contact. I wonder if the white is thicker? My understanding is they are important to prevent overclocking the weights. The weights do have contact closer to the end vs. the old clutches.

I agree that the cover seems awful light. It will flex if you goof around and tighten one side at a time. Lazy wrenchers might have issues.

Not sure if the roller bushings were changed? They were full length, but in two sections pressed from each side.

I compared the weights on two new sets last season. The low to high variance was .31 g with two outliers making up most of the difference. I also checked roller to weight variance on a few clutches. They were pretty close and within .007 on the worst one. I had some old clutches that were off by quite a bit. I had a TEAM that was almost .030 right out of the box.

I'd agree that the helix bolts seem short. I have not had any of these break loose. I do keep spare sets on hand and swap in new if they've seen multiple rounds. That's an old habit I still use. I also like to clean the threads to make sure they get correct torque with such short contact area.

-

2

2

-

-

13 hours ago, krom said:

That grey piece pivots out of the way,

The thing moves down pretty easy.

I also tore the light gray foam out around the clutch. I'd recommend doing that before the glue really sets. It's still fairly tight. I turn the clutch with the belt shoved between towers.

-

On 12/17/2023 at 7:04 PM, Palu49 said:

They did it during break in with the electronic oil pump too it’s getting a fuck ton of oil and not sucking it all through starting it up and letting it idle “heat cycling” it

They use more oil with the electronic pump during the early break in. Nobody ever mixed break in tanks at that ratio.

We bring extra oil for the first rides with new sleds. It's crazy how much they use.

-

3

3

-

-

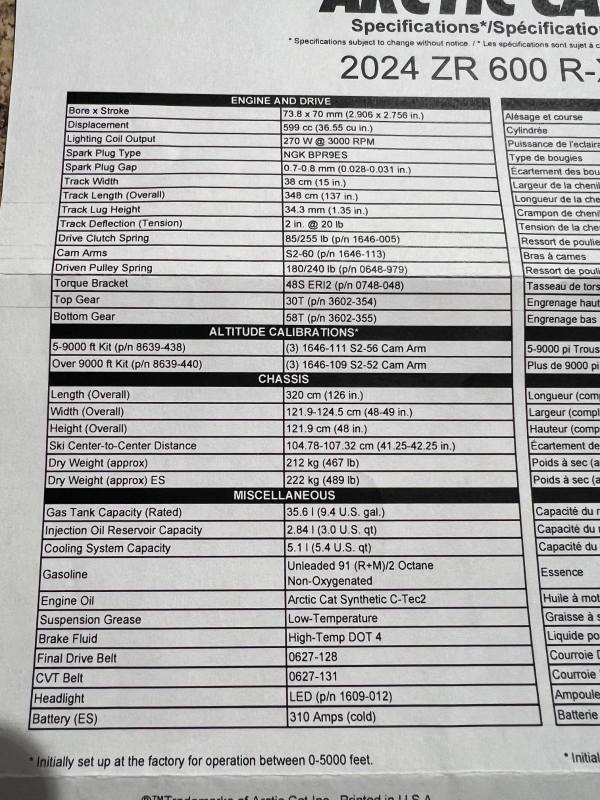

On 12/10/2023 at 8:58 AM, jonlafon1 said:

Thanks for posting the spec sheet.

The secondary info is nice to know.

I'm guessing that is a straight cut helix? I'm never sure with some of the numbers I've seen over the years.

It looks like the same secondary they have used with earlier RXC sleds. The primary is setup different. Those 60g weights and high finish rate spring could be interesting. I'm guessing we will see some screaming rpms on these.

I wonder if the other models are running the same clutching? Can't find the parts diagrams.

-

1

1

-

-

I figured the panel would bend enough to slide the belt through. Is that not possible?

It looks like popping the primary cover and changing springs might be tight. I've done that quite a few times during trips and it used to be pretty easy.

-

1

1

-

2024 Arctic Cat Catalyst 'Chassis' details?

in HCS General Forum

Posted

That's great info.

I did the same thing with weights. Dang glad I found the altitude kit pricing. The Cat profile isn't too bad and they have held up longer than adjustables in my experience.

I'm not really a top speed guy. I do tend to ride fairly fast and I've been trying to find something that holds up for high speed long hauls.

Been throwing together a few different secondary setups to try.

I found promo pricing on a M secondary with the 48S helix. Already had a couple of 155/220 springs so I built one of those combos. I'm impressed the primary with big weights pulled that secondary. If we get snow I'm thinking about trying the 64g. Seems like I'd need a little heavier initial rate on the primary spring to rev up those weights. I bet the finish rate is dang close.